Molybdenum Bar

Introduction

Molybdenum bar can be sintered and swaged, with purity over 99.80%. The main applications are additive in steel smelting industry and parts in electronic and semi-conductor industry.

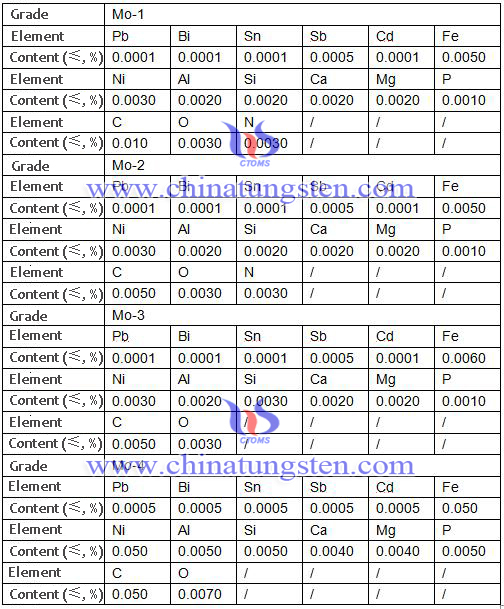

Grade

Mo-1, Mo-2, Mo-3, Mo-4

Chemicals

Specification(mm)

Round Bar: (15~20)X (15~20)x(250~800)

Rectangle Bar: Ø(15~30)X(250~800)

Physical Properties

Mo-2/Mo-3 Density≥9.3g/cm3

Chemical Property

Molybdenum bar remains stable at normal atmospheric temperature,and is slightly oxide at 400℃. When the temperature is higher to 600℃, its surface will oxide to mo oxides.

Manufacture Process

Powder Metallurgy: Molybdenum Powder→Weigh→Isostatic Press→Blank Bar→Sinter→Inspect→Finished Products

When the bar is used to make parts of semiconductor and electronic, the processes of swaging and machining are required.

Application

The bar with grade Mo-1 is used as additive in steel smelting industry. Mo-2 and Mo-3 are as machining materials. Mo-4 is applied as electrode.

Advantages of Molybdenum in Steel Alloys

Improve the hardenability and tempering stability of steel alloy

Chinese Standard

The Chinese standard clarifies the requirements, testing method, testing rules, packing, transportation, storage and contract of molybdenum bar and blank molybdenum plate. Details please visit GBT-3462-2007.

3TG Conflict Minerals Free Statement

Conflict Minerals Policy Statement

Material Safety Data Sheet (MSDS)

Material Safety Data Sheet (MSDS) can be reached and downloaded

Pictures

More pictures of molybdenum bar, please visit Chinatungsten Picture Bank.

Market and Price

Price and market daily, please focus on our wechat official account of Chinatungsten visit Chinatungsten price website.